B.IRD: IRD technology now for all processes

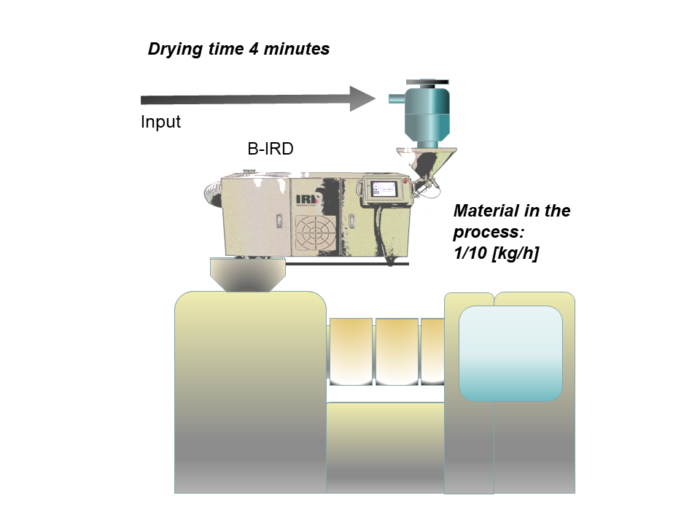

IRD technology has proven itself for larger volume throughputs in industrial series production for around 20 years. The further development B.IRD now makes it possible to use the pioneering drying and heating technology economically also for processing methods such as injection molding, where smaller quantities are required.

B.IRD: Maximum performance with minimum effort

Almost every injection molder is familiar with the inhibiting effort required by conventional drying.

Provision of hot drying air in a closed overall system, planning and handling of hour-long pre-runs, multiple and over-drying due to process interruptions, desiccant regeneration, dew point discussions and and … this has become a proverbial “science in itself”.

B.IRD reduces this effort to a minimum. You no longer have to deal with hot air, but may concentrate on the material and your core processes.

B.IRD: More than mere drying!

In principle, B.IRD is also suitable for a whole range of tasks beyond injection molding. Whether surface drying for sprinkled plastic quantities, deep drying for small-quantity compounding, odor reduction and decontamination during recycling or other tasks – contact us and we will check the possibilities with you.

We are currently working on a major project with IKV Aachen for use as pre-plasticization for processing operations. Friction in the process can be significantly and efficiently reduced with B.IRD. The gentle preparation of the plastics reduces the energy required for the overall process while at the same time significantly increasing material efficiency. Series tests for drying ABS and PC have already shown significant reductions in defective part production rates.

Other bulk materials of all kinds can also be heat treated and dried quickly. Whether powders, foodstuffs or minerals – in principle, all bulk materials are accessible to infrared treatment through the rotary drum technology.